SIMPLIFYING CLEANROOM DELIVERY

THE POD® DESIGN

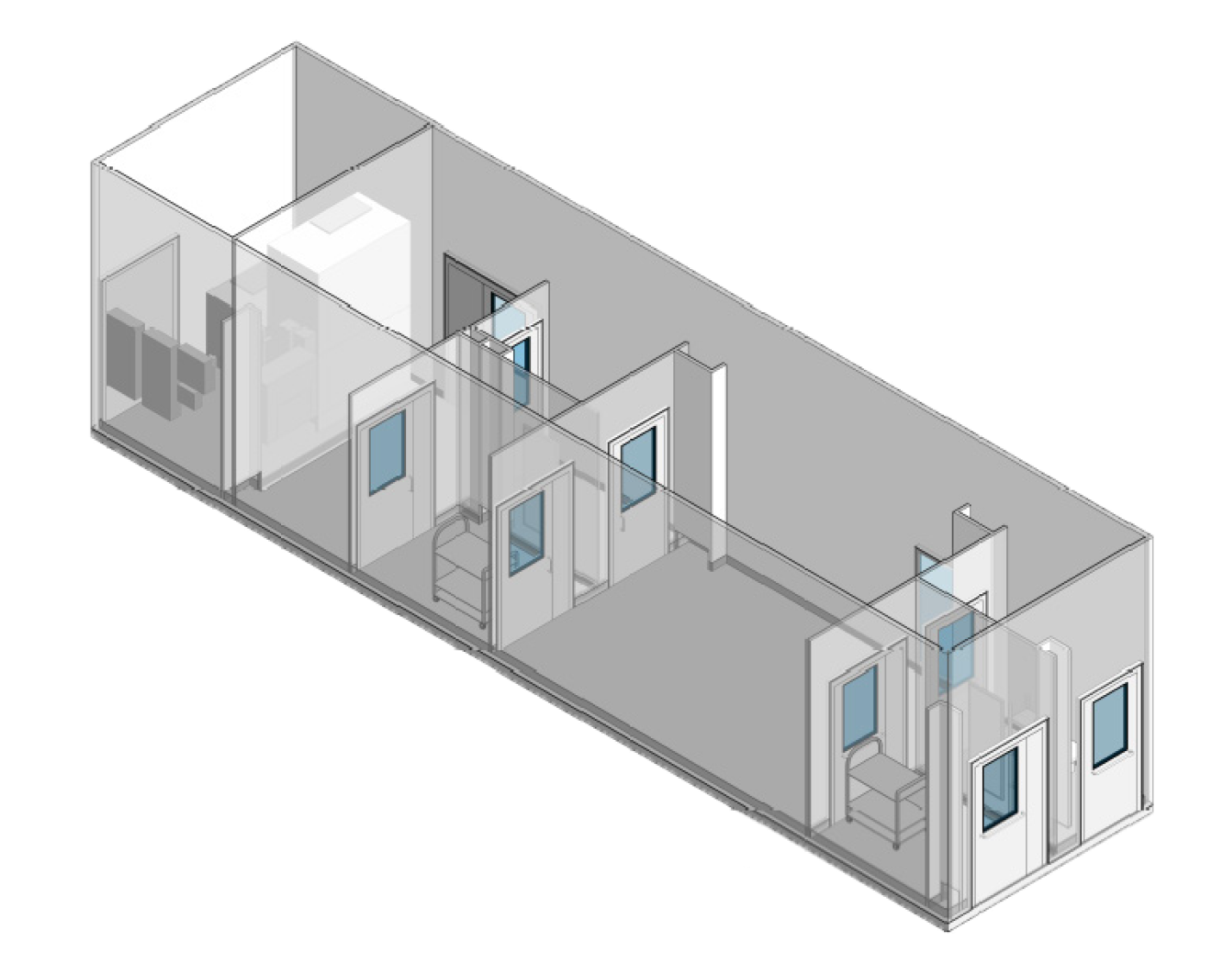

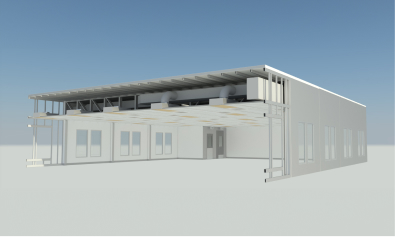

POD® Cleanrooms are prefabricated containment cleanroom systems built and fully commissioned to assure full functionality. POD® Cleanrooms are flexible, rapidly deployed, scalable, repurposable and mobile due to integrated air bearings. POD® Cleanrooms require very little infrastructure to operate. They can sit in space as simple as a warehouse and only require power and in some instances water. They can be connected to provide contiguous cleanroom space or lined up against a corridor if segregation is required. Each POD typically has a separate mechanical area allowing service and maintenance on the POD to occur without interrupting operations.

FLEXIBLE. RAPIDLY DEPLOYED. SCALABLE.

QUALITY CLEANROOMS FOR PLUG AND PLAY DESIGN

01

MECHANICAL AREA

Accessed from "grey space". Available with failsafe HVAC.

02

STANDARD AND CUSTOM SIZES AVAILABLE

A variety of sizes are available to accommodate cleanroom area requirements.

03

MATERIAL AIRLOCKS

Optional material airlocks or gowning area available.

WHY CHOOSE PREFABRICATED CLEANROOMS FROM G-CON?

When speed, flexibility, and reliability matter most, prefabricated cleanrooms from G-CON offers an unbeatable solution. Prefabricated cleanrooms are designed and built off-site in a controlled environment, minimizing on-site construction challenges and dramatically accelerating project timelines. With G-CON’s POD technology, prefabricated cleanrooms arrive ready for rapid installation, ensuring faster validation and operational readiness for your facility.

SOLUTIONS TO FIT YOUR PROJECT APPLICATION

G-CON offers a wide variety of prefabricated cleanroom solutions ranging from our standardPODs to project specific POD® Cleanrooms. Our standard portfolio can accommodate most upstream and downstream processes. If site limitations are present or oversized process equipment is needed, G-CON can build a custom POD or series of POD® Cleanrooms. G-CON’s in-house engineering team can design a solution for your particular application, process or environmental needs using standard or custom POD® Cleanrooms. In either form, POD® Cleanrooms provide many standard features and finishes such that commissioning and validation will be streamlined as opposed to unique process for each cleanroom space.

Download Our BrochurePOD PRODUCTS

Whether standard or custom, every POD is fully designed and manufactured at G-CON's facility

Our POD® Cleanrooms are installed and commissioned to assure full functionality, and provided with a comprehensive engineering turnover package that provides full traceability of components, finishes, and structural details.

standardPOD

The standardPOD is an off-the-shelf cleanroom, with delivery in as little as 3 months. Our standardPOD offers six configurations and is the top choice for readily available, high quality standardized cleanrooms.

floorlessPOD

The floorlessPOD is the next generation of prefabricated cleanroom innovation, providing a free-standing structure while also allowing for direct integration with the host facility floor.

megaPOD

The megaPOD is a stackable POD solution for large process equipment and operations that require a higher cleanroom ceiling.

POD System

The POD System integrates multiple connected units to accommodate larger footprint installations with suites, airlocks, and corridors.